Combine Harvester Types - Conventional

- By: "Farm Tender" News

- Machinery & Equipment News

- Sep 17, 2024

- 1803 views

- Share

By Phil Rowntree - 0428 659 056 - philr@farmtender.com.au

All modern combines have the same task to achieve, and it is one of the most labour-saving inventions of its time: They are designed to

- Cut the crop

- Thresh the crop

- Separate the grain from the heads

- Clean the straw and chaff from the grain

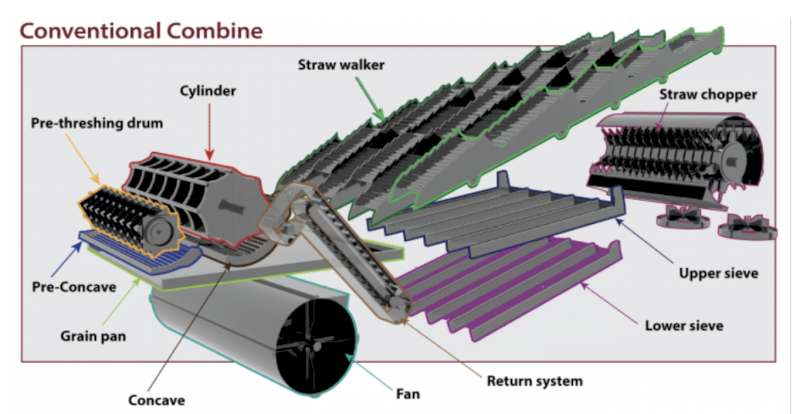

Conventional

Conventional combines have been used forever and a day. Using a rotating cylinder at the front to thresh the seeds from the heads and a walker system to remove straw.

The crop enters the threshing area via the feeder housing to be met by a pre-threshing drum, sometimes known as a pegged drum. This pegged drum will start the process of threshing the grain where the easily threshed grain will fall through the pre concave to the grain pan. Pre concave’s, usually depending on brand and model, can be swapped to suit different crops such as cereals and pulses.

From there the remaining un threshed crop, the majority, enters the threshing cylinder/drum passing between the cylinder rasp bars and the concave. Grain, chaff and smaller debris will fall through the concave to the grain pan. Clean grain is collected and moved to the grain tank.

Depending on crop conditions, the cylinder RPM and concave gap can be adjusted to suit. Examples being hard threshing of frosted cereals may require higher RPM and smaller concave gap. Disawning plates are also used at times of hard threshing.

Remaining straw will pass to the “straw walkers”. With the use of fans and gravity the remaining straw is separated from the grain passing to the rear of the machine and commonly passing to the spreading system via a chopper.

Advantages

- Straw quality for fodder

- Low horsepower requirement/fuel efficiency

Disadvantages

- Capacity lower than rotary.

- Ability to handle a wide range of crop types.

Share Ag News Via