Ag Tech News - Vermeer innovation concepts address Agriculture labor challenges

- By: "Farm Tender" News

- Ag Tech News

- Jul 17, 2021

- 872 views

- Share

Vermeer Corporation introduces four industry-leading concepts to help customers optimize their hay operations: a patent-pending autonomous bale mover, patent-pending onboard bearing temperature sensors, automated baling assistance technology and Forage Commander — a field data management app. These innovations are designed to help overcome the growing agricultural labor challenges and tight timelines producers continue to face.

“Our team is dedicated to developing practical ways to help forage producers make the most of their available labor and get the most out of their time in the field,” said Vermeer Research and Development Manager Kent Thompson. “We work to identify solutions that producers don’t even realize are possible, all focused around their hay operation.”

These advancements build on a history of innovation at Vermeer, which is celebrating 50 years of its large, round baler — an innovation that changed the way hay and forage producers feed and fuel the world.

Autonomous bale mover

The bale mover concept, nicknamed “Bale Hawk” will travel around the field autonomously via onboard sensors to locate bales, pick them up and move them to a predetermined location.

“This machine helps save labor time and associated costs, by eliminating the manual step of moving bales," said Thompson. "The autonomous bale mover senses where it is relative to a bale, allowing it to plan a route to pick up that bale. Today, it can pick up three bales at a time before delivering and unloading them to a predetermined location.

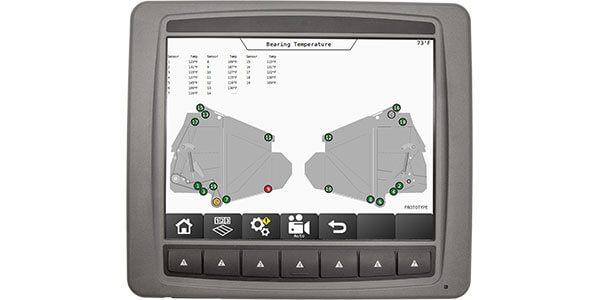

Onboard bearing temp sensors

These wireless, battery-powered temperature sensors will help operators monitor baler bearing temperatures from the cab, helping to provide predictive maintenance notices to operators before the bearing reaches its end-of-life.

“When given this information ahead of time, operators can order new bearings and replace them before they reach the end-of-life or fail due to contamination, which helps keep balers in the field when it matters most,” said Vermeer Forage Innovations Senior Engineer Nathan Dockter.

Automated baling assistance technology

This windrow guidance system for the Vermeer ZR5-1200 self-propelled baler will use light detection and ranging (LiDAR) sensors to track the windrow and automatically steer the machine.

“The automation can allow the operator to focus on other aspects of the baling process — it is a step towards us taking the guesswork out of creating a consistent, good-looking bale,” said Vermeer Forage Innovations Senior Systems Engineer Gary Burns.

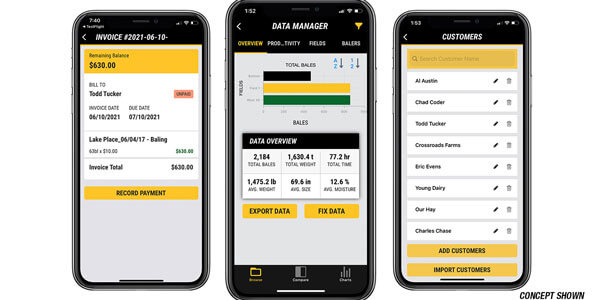

Field data management app

The Forage Commander app will connect the user's smart device via Bluetooth to the data gateway unit located on the baler to provide the latest field stats for each customer, including bale weight, bale moisture, bales per hour and more. From this data and customer information, the Forage Commander can generate an invoice to email directly to the operator’s customer.

“This app is really designed for an operator who wants to better understand their productivity in the field or is looking for a more convenient tool to help manage their custom hay operation,” said Vermeer Product Manager Shawn Wang.

To learn more about Vermeer innovations, visit vermeer.com/innovation.

About Vermeer Corporation

Vermeer delivers a real impact on the way important work gets done through the manufacture of high-quality agricultural, underground construction, surface mining, tree care and environmental equipment. With a reputation for being build tough and built in a better way, that equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer, products, the dealer network and financing options, visit vermeer.com.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Share Ag News Via